The new designs for the lift station were drafted and discussed by the engineering firm, the property management company, the on-site construction team and AQUALIS. Through this communication, the ongoing redevelopment and lift station rehabilitation were able to be completed without delays. The designed plan included enlarging the access to the well and rebuilding the internal components of the station.

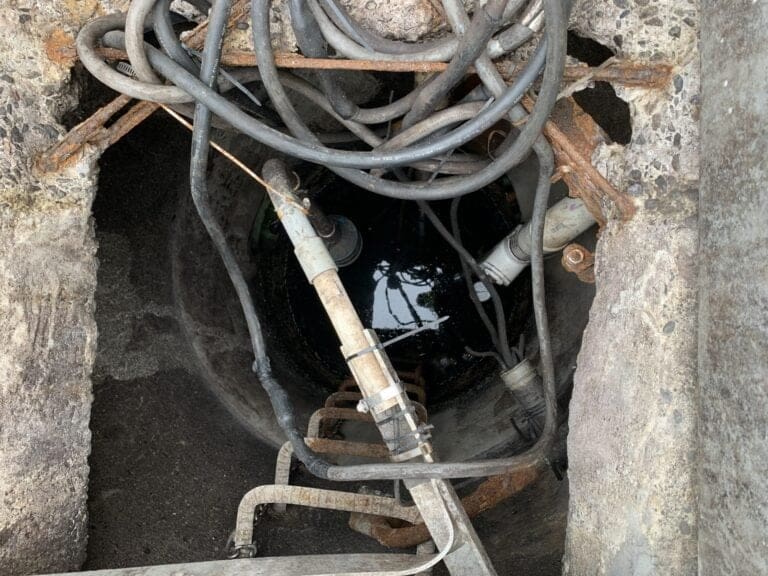

To begin, the existing station had to be completely accessible. The current station access was crudely carved through concrete and rebar and would not be able to accommodate the redesign size requirement. The concrete and rebar were removed to allow for visualization of the internal components.

Due to the ongoing construction, all facilities were confirmed to be offline, eliminating the need for a diversion system. As a precaution, plugs were installed around inlet and outlet pipes to block water from entering the pipes. The lift station was dewatered to be cleaned and prepared for relining. Relining was necessary as overtime sewage creates hydrosulfide gas that is highly corrosive and can damage and dissolve the internal components of lift stations including pumps, pipes and concrete walls. To properly repair the walls, the internal pumps and pipes were removed, as they were also being replaced.

A spray-on liner was chosen to coat the internal structure, originally constructed from concrete. The new liner filled any potential cracks or leaks in the well and ensured a prolonged life for the structure. Moving quickly to not disturb construction, AQUALIS rebuilt the internal components to adjust for the new expected capacity.

The size of the basin is crucial to the success of the station as the capacity must be appropriate for the expected flow. A basin that is too small introduces the risk of flooding, but larger basins are expensive to install and may lead to prolonged periods of still water which can lead to smells and expedite corrosion. The basin was resized to accommodate for the expected new flow and a new manhole opening was designed for easier access.

Both pumps and pump bases were replaced and a third spare pump was provided to minimize turnaround time in the event of pump failure. New guide rails to allow access to the pumps, internal and a level monitoring system were installed. Internal piping of the station included discharge pipe, isolation valves and check valves. The level monitoring system was relocated inside the wet well to the appropriate height. It was previously routed through the center of the access hole making it difficult to enter the wet well as well as preventing the possibility of installing a guide rail system to accommodate pulling and inspecting the pumps. The new configuration allowed for easy access for maintenance and potential repairs. Rehabilitation was finalized and the system now has the capacity and ability to handle the proposed increase in volume.

With a regular maintenance plan for the new system, this property is set up for success with additional capacity.

About Lift Stations:

Lift stations can be prefabricated or professionally engineered and installed in commercial or residential properties. Submersible lift stations are a popular choice as they are less expensive to design, can be hidden underground and require simpler operation and maintenance in comparison to dry well lift stations. Submersible stations are a preferred practice in geographical areas that experience potential freezing temperatures. They are also suitable for installation inside of facilities if there is not a practical location on the exterior. Alternatively, above ground systems are common in areas in the southern United States that do not risk components freezing but do require the space above grade. Those lift station systems are utilized in areas where the water table is high like Florida. As this property experiences freezing temperature often, a submersible lift station is the most appropriate choice. This submerged lift station was already located under the high traffic entrance to the parking garage, so it was most appropriate to redesign during redevelopment when the property was vacant.

Lift stations automatically pump water once the volume reaches a certain level inside the basin, the level monitoring system activates the pump, and the pump shuts off when the water level lowers to a designated height. The pump is notified to shut off via the level monitoring system, which is designed and operated a number of ways. The benefit of the sonar device is grease and other surface buildup do not affect the level control system alleviating the potential for costly backups and flows common with other monitoring methods.

AQUALIS is capable of supporting lift station issues nationwide. If you have questions about a lift station located on your property, reach out to AQUALIS today for a consultation.

Kenosha, Wis. Highway KR Regenerative Stormwater ConveyanceThe Root-Pike Watershed Initiative Network Kenosha County, and others worked with AQUALIS to design and implement an innovative solution for stormwater control along Highway KR.

Kenosha, Wis. Highway KR Regenerative Stormwater ConveyanceThe Root-Pike Watershed Initiative Network Kenosha County, and others worked with AQUALIS to design and implement an innovative solution for stormwater control along Highway KR. Durham, N.C. Sinkhole Leads to Stormwater System RehabilitationThe tenant on this property noticed a depression that opened to the ground below and notified the property owners.

Durham, N.C. Sinkhole Leads to Stormwater System RehabilitationThe tenant on this property noticed a depression that opened to the ground below and notified the property owners.